Repairing Water Pipes

LiSCaP has worked to improve the LWB’s leak repair methods and the review of materials used for repair works. The works included the enhancement of safe work on the pipe repair, efficient repair work, and repair recording that is necessary for future activities and planning. Safety work focused on the removal method of asbestos concrete (AC) pipe in the system. Considering the health hazards of asbestos dust, the experts initiated wearing of personal protective equipment (masks, glasses, rain gear) and preventing the spread of asbestos dust during work as a priority.

As a result, the awareness of AC pipe safety work was raised, and LWB moves to procure the adequate number of personal protective equipment and tools for the same purpose. Previously the pipe repair works were not recorded for small leaks such as “so- called leakage”. After improving the format of leakage record, however, records by plumbers are now being implemented entirely.

In improving the pipe repair methods, frequent leakages were discovered in exposed distribution and service pipes of the supply network. As a countermeasure against them, LWB conducts “pipe lowering” by re-installing pipes at lower level. Furthermore, LiSCaP introduced the use of properly selected soil for backfilling and put much emphasis on conducting enough compaction when backfilling trenches so that the repaired pipe would not be re-exposed.

Implementation of Leak Detection Activities

LiSCaP had selected four pilot DMAs within the supply area of Southern Zone, to conduct trial activities for non-revenue water reduction. In the field of leak detection, LiSCaP provided survey equipment and technical support for leak detection. In this project, we measured the Minimum Night Flow rate (Qmnf), which is the flow rate in the distribution pipes measured late at night when consumption is the lowest, with the assumption that no customer uses the suppled water during this time hence enabling estimates of the amount of leakage from the measured data of the entire target DMA. For LWB. Leak detection activities were an inexperienced field in LWB, a condition that necessitated formulation of a Leak Detection team, which after explanation of each work items and technical terms related to leak detection by the experts, conducted an on-site survey and demonstration practices in the DMA

As a practice to efficiently hunt down leaks in distribution network in a large area, the target DMA was subdivided into sub-zones, where upon confirming the distribution of leakage, step-tests are conducted by conducting leak detection activities in priority subzones. According to the priority set by the step test, the team carried out door-to-door survey persistently and thoroughly for each customer meter in the sub-zone. They utilized Listening stick to identify the sound generated when water leaks from a water pipe, and when leakage was suspected a leak detector was used to pin point the exact location of the leakage. As a result, 55 leakages were found in the first pilot DMA. The identified leaks were quickly repaired, and Qmnf was reduced by about 4.0 m3 / h.

Toward Proper Billing of Water Meters

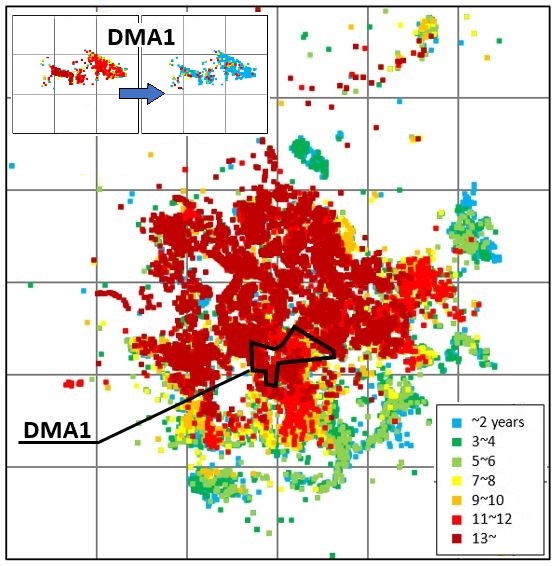

WB water meter service life time from installation to replacement is estimated at a period of 8 years. Looking at the meter ages installed in Southern Zone areaa large percentage of meters situated in the areas developed earlier in the city are more than 8 years old (shown in yellow, orange, red, and dark red in Fig. 1), were some are even 15 years old or more. Citing an example of the first Pilot DMA which has around 1,000 water meters, about 60% of them are over 8 years old.

As a practice to efficiently hunt down leaks in distribution network in a large area, the target DMA was subdivided into sub-zones, where upon confirming the distribution of leakage, step-tests are conducted by conducting leak detection activities in priority subzones. According to the priority set by the step test, the team carried out door-to-door survey persistently and thoroughly for each customer meter in the sub-zone. They utilized Listening stick to identify the sound generated when water leaks from a water pipe, and when leakage was suspected a leak detector was used to pin point the exact location of the leakage. As a result, 55 leakages were found in the first pilot DMA. The identified leaks were quickly repaired, and Qmnf was reduced by about 4.0 m3 / h.